Hagaajinta farqiga u dhexeeya rullaluistemadka cadaadiska iyo caaryada giraanta ee granulator waa qayb muhiim ah oo ka mid ah hawlgalka granulator-ka. Haddii farqiga farqiga u yahay mid macquul ah, granulator-ku wuxuu yeelan doonaa wax soo saar sare, isticmaalka tamarta yar, tayada walxaha wanaagsan, xirashada hoose ee rollerka cadaadiska iyo caaryada giraanta, iyo nolol adeeg oo dheer.

Granulator-ku si sax ah uma shaqeyn karo, tayada walxaha lama dammaanad qaadayo, iyo haddii farqiga u dhexeeya rullaluistemadka cadaadiska iyo caaryada giraantu ay aad u yar tahay, waxay si daran u xiran doontaa, xitaa waxay sababi kartaa caaryada giraanta inay dillaacdo. Tani waxay soo bandhigaysaa shuruudo sare oo loogu talagalay hawl-wadeenada granulator-ka, kuwaas oo u baahan inay aqoon qani ah u yeeshaan hagaajinta rullalulatada cadaadiska. Si loo yareeyo saameynta waxyaabaha aan xasilloonayn ee ay keenaan hawlgallada aadanaha, iyo sidoo kale in la yareeyo xoogga shaqada aadanaha iyo hagaajinta waxtarka wax soo saarka.

Farqiga u dhexeeya rullaluistemadka cadaadiska iyo caaryada giraanta ayaa soo baxday.

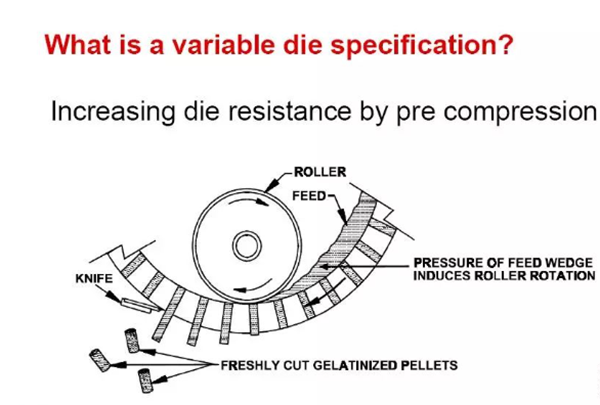

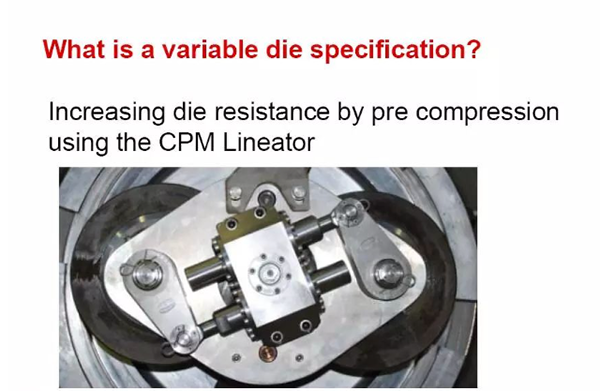

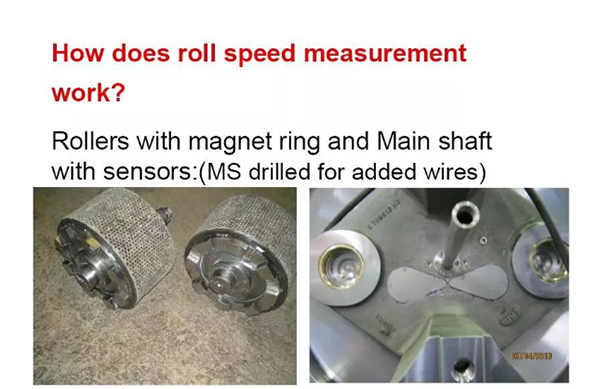

Mabaadi'da farsamada:

Nidaamku wuxuu inta badan ka kooban yahay nidaamka fulinta dhululubada saliidda, dareemaha xagasha, iyo nidaamka xakamaynta PLC. Shaqada nidaamka fulinta dhululubada saliidda waa in la riixo rullaluistemadka cadaadiska si uu u wareego saacadda ama saacadda, xitaa haddii farqiga u dhexeeya rullaluistemadka cadaadiska iyo caaryada giraanta ay korodho ama hoos u dhacdo;

Shaqada dareemaha xagasha waa in la dareemo isbeddelada xagasha rollerka cadaadiska oo u gudbiya calaamadda isbeddelka nidaamka xakamaynta PLC; Nidaamka xakamaynta PLC wuxuu mas'uul ka yahay beddelka isbeddelka xagasha rullaluistemadka cadaadiska isbeddelka cabbirka farqiga u dhexeeya rullaluistemadka cadaadiska iyo caaryada giraanta, iyo isbarbardhigga qiimaha farqiga u dhigma si loo go'aamiyo jihada iyo cabbirka nidaamka fulinta dhululubada saliidda ilaa farqiga dhabta ah iyo farqiga go'an ay ku habboon yihiin gudaha xadka la oggol yahay ee qaladka.

Faa'iidooyinka farsamada:

Shaashadda taabashada goobta waxay u adeegtaa sida isdhexgalka isdhexgalka, taas oo sahlaysa in la shaqeeyo;

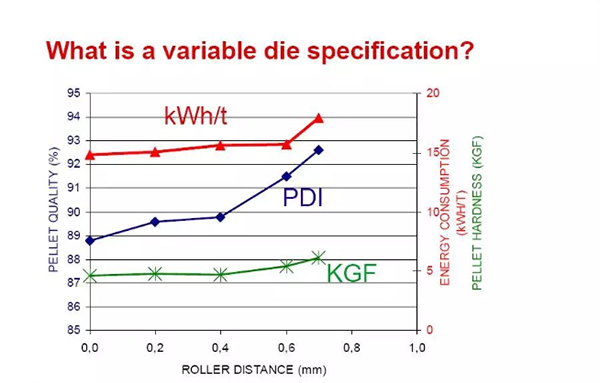

Iska yaree biraha iyo taabashada birta, yarayso xidhashada rollerka cadaadiska iyo caaryada giraanta, si weyn u kordhinaysa nolosha adeegga;

Yaree baahida korantada, yarayso wakhtiga, oo badbaadi wakhtiga iyo kharashyada;

Saxnaanta hagaajinta sare, qaladka farqiga u dhexeeya rullaluistemadka cadaadiska iyo caaryada giraanta waxaa lagu xakameyn karaa gudaha ± 0.1mm;

Waa la hagaajin karaa wakhti kasta inta lagu jiro hawlgalka granulator, si weyn u hagaajinaya kalsoonida shaqada iyo hufnaanta, iyo yaraynta xoojinta shaqada;

Ma jiro saliid saliid leh, kordhinta badbaadada quudinta.

Waqtiga boostada: Jul-12-2023