Isku-dhafka Quudinta Digaagga SDHJ/SSHJ

Qiyaasaha Farsamada

| Qaabka | Mugga (m³) | Awoodda/dufcada (kg) | Wakhtiga isku darka | Homogeneity (CV ≤%) | Awood (kw) |

| SSHJ0.1 | 0.1 | 50 | 30-120 | 5 | 2.2 (3) |

| SSHJ0.2 | 0.2 | 100 | 30-120 | 5 | 3 (4) |

| SSHJ0.5 | 0.5 | 250 | 30-120 | 5 | 5.5 (7.5) |

| SSHJ1 | 1 | 500 | 30-120 | 5 | 11 (15) |

| SSHJ2 | 2 | 1000 | 30-120 | 5 | 15 (18.5) |

| SSHJ3 | 3 | 1500 | 30-120 | 5 | 22 |

| SSHJ4 | 4 | 2000 | 30-120 | 5 | 22 (30) |

| SSHJ6 | 6 | 3000 | 30-120 | 5 | 37 (45) |

| SSHJ8 | 8 | 4000 | 30-120 | 5 | 45(55 |

| Shaxda cabbirrada Farsamada ee Taxanaha SDHJ | ||

| Qaabka | Isku dhafka Awoodda Dufcaddiiba (kg) | Awood (kw) |

| SDHJ0.5 | 250 | 5.5/7.5 |

| SDHJ1 | 500 | 11/15 |

| SDHJ2 | 1000 | 18.5/22 |

| SDHJ4 | 2000 | 37/45 |

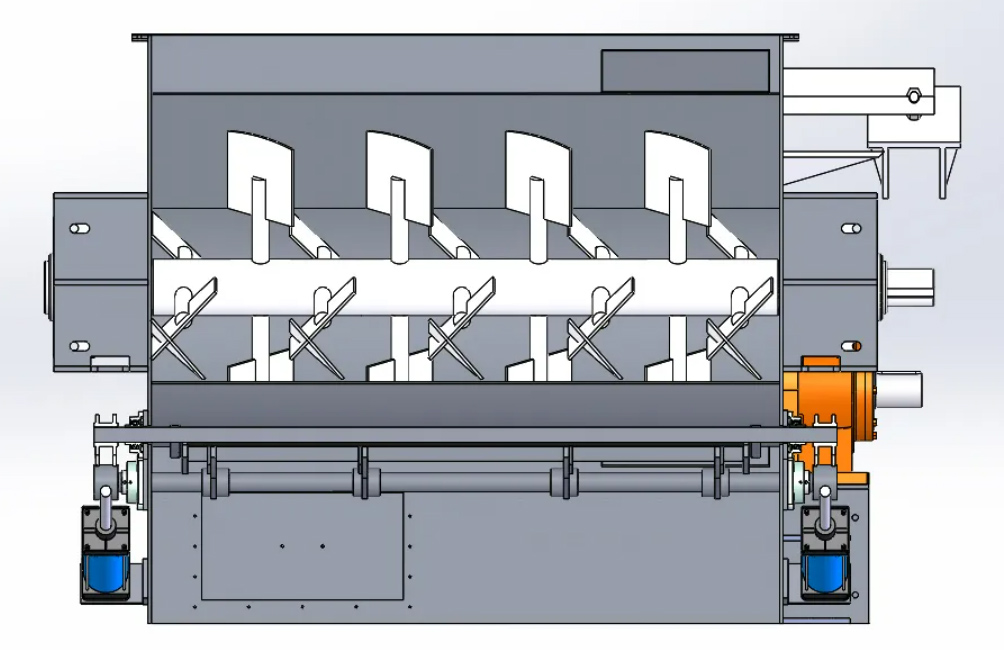

Bandhiga Alaabta

Macluumaadka Alaabta

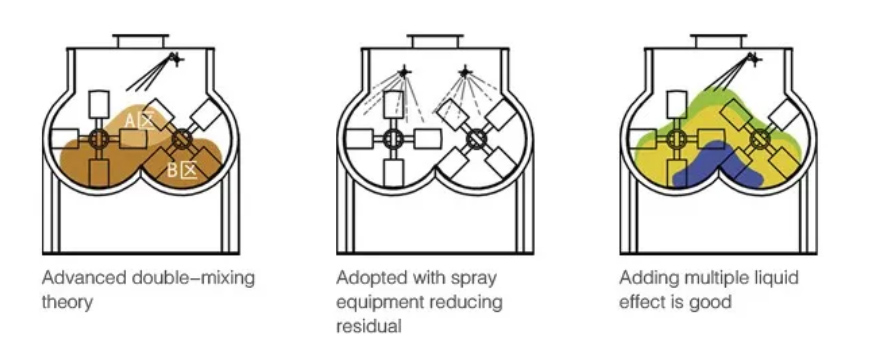

Isku darka quudinta ayaa ah tillaabo muhim ah ee habka wax soo saarka quudinta. Haddii quudinta aan si habboon loo qasin, maaddooyinka iyo nafaqeeyayaalka si sax ah looma qaybin doono marka loo baahdo extrusion iyo granulation, ama haddii quudinta loo isticmaalo sida mash. Sidaa darteedIsku-darka quudinta ayaa door muhiim ah ka ciyaara geedka pellet quudinta sidiisabasi toos ah u saameeya tayada pellets quudinta.

Isku darka digaaga digaaga waxay u adeegaan inay si isku mid ah isugu daraan budada alaabta ceeriin ee kala duwan, mararka qaarkood waxay u baahan yihiin isticmaalka qalabka lagu daro dareeraha si loogu daro nafaqooyinka dareeraha si si fiican loo isku daro. Ka dib marka la isku daro heer sare ah, maaddadu waxay diyaar u tahay soo saarista pellets quudinta tayada sare leh.

Isku-dhafka digaaga digaaga waxay ku yimaadaan cabbirro iyo awoodo kala duwan iyadoo ku xiran hadba inta quudinta loo baahan yahay. Mashiinnada qaarkood waxay farsamayn karaan boqollaal kiiloogaraam oo quudin ah dufcaddiiba, halka kuwa kalena ay isku qasi karaan tan oo quudin ah markiiba.

Mashiinku waxa uu ka kooban yahay baaldi ama durbaan weyn oo leh baaldi ama baallo wareeg ah oo miiqan oo isku dara maaddooyinka marka lagu daro baaldiga. Xawaaraha ay daabyadu wareegaan waa la hagaajin karaa si loo hubiyo isku darka saxda ah. Qaar ka mid ah isku darka quudinta digaaga ayaa sidoo kale waxaa ka mid ah nidaamka miisaanka si loo cabbiro qadarka saxda ah ee walxo kasta oo lagu daray quudinta.

Marka maaddooyinka si fiican loo qaso, quudinta ayaa laga soo daayaa gunta hoose ee mishiinka ama waxaa loo qaadaa meel lagu kaydiyo si hadhow loogu qaybiyo beerta digaaga.