Mashiinka Samaynta Qoryaha Pellet Mill Pellet

Tilmaamaha ugu muhiimsan

1. Baaxadda lagu dabaqi karo oo ballaaran

Waxay farsamayn kartaa waxyaabo kala duwan sida galleyda, galleyda, cawska, hadhuudhka, SBM, MBM, alfalfa, molasses, caws, iyo qaar ka mid ah alaabta ceeriin.

2. Habka pellet feed oo dhamaystiran

Xariiqda wax-soo-saarka xooluhu waxay ka kooban yihiin helidda iyo nadiifinta, shiididda, dufanka iyo isku-darka, diirinta, qaboojinta, burburka, baadhista iyo xidhidhaynta qaybaha pellets.Khadka buuxa waxa uu ka kooban yahay burburiye, qase, mishiinka pellet, qaboojiye, qolof leh, qaboojiye iyo dhammaan haamaha, baadhida, alaab-qaadayaasha mishiinada, iwm. Waxaanu u qaabayn doonaa shaxda qulqulka pellet oo buuxa iyadoo loo eegayo alaabtaada cayriin iyo shuruudaha gaarka ah.

3. Pellets quudinta dhammaatay oo tayo wanaagsan

Qaboojiyaha birta ah waxay kordhiyaan qaboojinta iyo wakhtiga karinta.Dekadda buufinta uumiga Axial, hagaajinta waxtarka cunto karinta.

4. Mashiinnada quudinta tayo sare leh

Qalabka ugu muhiimsan ee wadista saxda ah ee saxda ah iyo usheeda dhexe waxay qaataan deminta kaarboonaynta iyo tignoolajiyada iligga adag ee shiida, taasoo keentay wadista siman, buuq yar iyo nolosha adeeg dheer.

5. Awoodda la habeeyey

Waxaan astaysto awoodaha kala duwan laga bilaabo 1 tan saacaddii ilaa 50 tan saacaddii ama xataa ka badan.

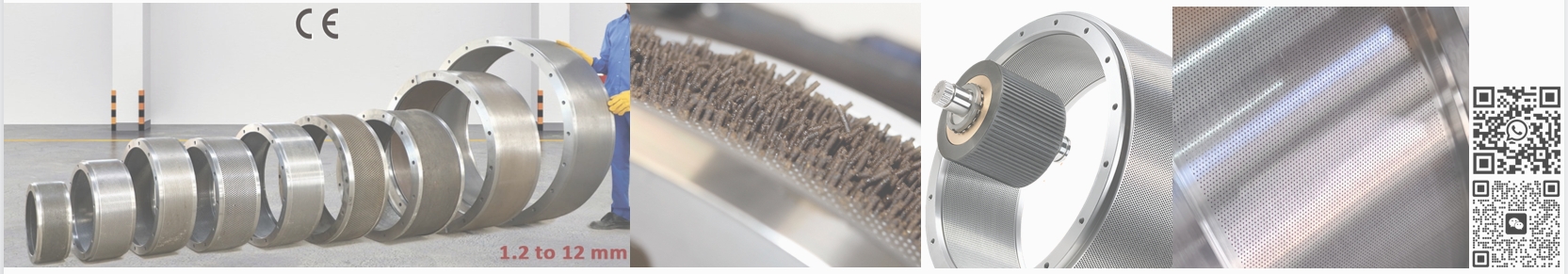

6. Noocyada iyo cabbirrada kala duwan ee quudinta

Waxaan u habayn karnaa xalalka soo saarista quudinta mash-ka, quudinta pellet, iyo quudinta crumble adiga.Cabbirka quudinta pellet wuxuu noqon karaa 1.5mm ilaa 18mm.

Halbeegyada Farsamo ee ugu muhiimsan

| Shayga | Qiyaasaha Farsamada | |||||||

| Qaabka | MZLH250 | MZLH320 | MZLH350 | MZLH400 | MZLH420 | MZLH508 | MZLH600 | |

| Awoodda (t/saac) | 0.1-0.2 | 0.2-0.4 | 0.5-0.7 | 0.7-1.0 | 1-1.5 | 1.5-2.0 | 2-2.5 | |

| Awood (kw) | Matoorka ugu muhiimsan | 155 | 37 | 55 | 75/90 | 90/110 | 110/132/160 | 185/200 |

| Quudiye | 0.55 | 0.55 | 0.75 | 1.5 | 1.5 | 1.5 | 2.2 | |

| qaboojiyaha | 2.2 | 2.2 | 3 | 5.5 | 5.5 | 11 | 11 | |

| Dhexroorka gudaha ee giraanta (mm) | φ250mm | φ320mm | φ350mm | φ400mm | φ420mm | φ508mm | φ600mm | |

| Balaadhka waxtarka leh (mm) | 60mm | 60mm | 60mm | 80mm | 100mm | 120mm | 120mm | |

| Xawaaraha wareega(rmp) | Giraanta Geerida | 360 | 220 | 215 | 163 | 163 | 186 | 132 |

| Quudiye | 12-120 | 12-120 | 12-120 | 12-120 | 12-120 | 12-120 | 12-120 | |

| qaboojiyaha | 300 | 300 | 300 | 270 | 270 | 270 | 270 | |

| Cabbirka Pellet (mm) | φ6-10mm | φ6-10mm | φ6-10mm | φ6-10mm | φ6-10mm | φ6-10mm | φ6-10mm | |

| Lambarka galootiga | 2 | 2 | 2 | 2 | 2 | 2 | 2 | |

Bandhiga Alaabta